I

removed the coil bracket from the the master cylinder frame cover, then

removed the cover, revealing the brake and clutch MC push rods.

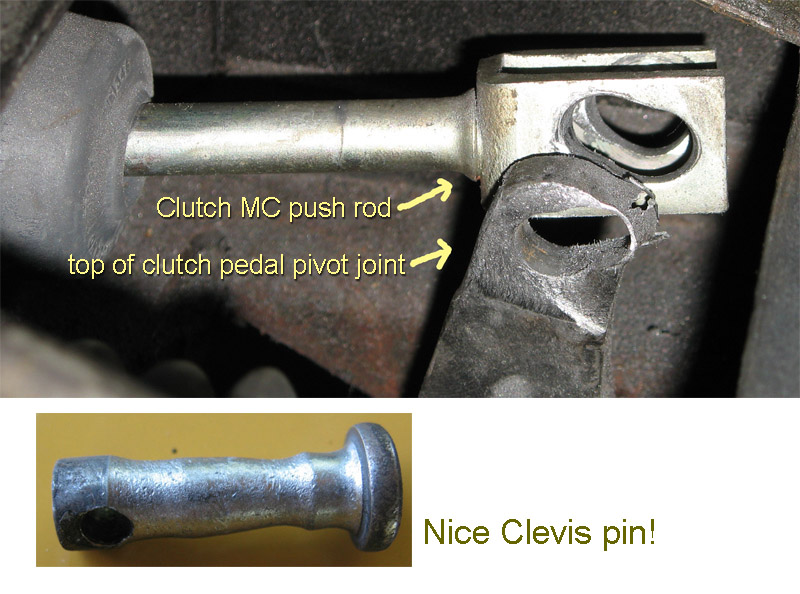

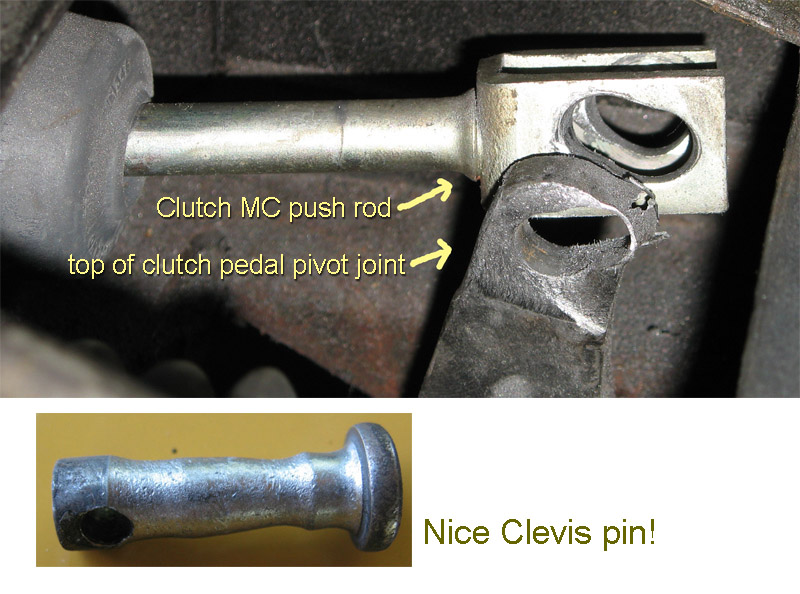

Here is what the clutch MC push rod looked like.

|

|

The

top of the clutch pedal pivot joint looked no better.

So here is the reason for the 40-50mm of free play

on my clutch pedal. The push rod never made it all the way into

the MC when I stepped on the clutch - you know the results.

The clevis pin showed a bit of wear (!)

|

|

The

clutch master cylinder push rod is held in with a large washer which in

turn is held in place by a snap ring.

Given the difficulty involved in detaching the clutch MC from it's

frame, because of an inaccessible nut at the bottom, I had hoped I

could get the snap ring out with the MC in place. This was not to

be. I, and my tools, could not contort into the necessary shape.

|

|

So

then the next best thing would be to remove the clutch MC from it's

frame, while keeping it's fluid line attached, and not disturbing the

brake MC at all. I unbolted the frame, then lifted up the back

end about 4" and stuck a wooden block under it to keep it in

place. From there I was able to get a wrench to the bottom nut

holding in the clutch MC. Mercifully the piping leading away from

the brake MC was not adversly effected by a little twisting!

In this photo the clutch MC is still in place, with it's orange tubing

running away from it.

|

|

Upon

removing the clip, the push rod came out and the piston immediately

revealed itself.

|

|

Here

is

the old push rod and the new, with the the rubber

and ring clip moved

over to the new one.

|

|

To

get the ring clip back in with a minimum of fuss, I compressed the

clutch MC push rod all the way, then used some wire to hold it in

place.

I also flipped the rubber cover to get it a bit more out of the way.

Then getting the clip on was no problem. |

|

Here

is the new clevis pin resting on the clutch pedal pivot point. A

lot of metal sure was ground off of the clutch pedal over the last 30

yeaars!

My plan is to NOT remove the clutch pedal, and to fill the space

between the clevis pin and the distorted edge of the hole with a

fast-setting two-part epoxy putty. (Please note that this is not

really the best or safest solution - getting a new pedal, or welding

the bad one is preferable. But regardless of all that...)

|

|

I

wrapped the clevis pin in saran wrap. Then I was able to use the

in-place pin as a form to pack epoxy putty around, when building up the

pedal.

|

|

Here's

the stuff. It hardens in 5 minutes or less, so plan ahead!

$5 or so at home depot in the plumbing dept. Just slice off a bit

and knead to activate.

|

|

Here

is the putty packed around the clevis pin, filling the distorted area,

and built up a bit beyond it

|

|

After

ten minutes or so, I pulled out the clevis pin and filed down the

excess putty

|

|

Here

are the parts in place.

Things are working much better now. The free play on the clutch pedal

has been reduced to a 1/8" or less, and shifting to all gears is

fine.

I have since purchased a good clutch pedal from a listmember.

Though my fix seems to be holding up well, and has taken the car about

300 miles as of this writing, there's no guarantee that the putty will

hold together forever.

|

|